Creating the M22 and ESCC™ was no small feat- it was a long journey full of adversity, discovery and growth.

The Beginning of the Molecule series.

In 2018 customers of the original 15mm Molecule RDA asked us to make a crucible for it. Our first attempt was a quartz insert on top of a flat stainless steel coil. It didn't work very well and so we tried a coil embedded into a ceramic donut. We then secured various crucible materials against the ceramic coil. This still resulted in unsatisfactory results and is how other companies currently do crucible vapes.

External heating is very inefficient and too much energy is wasted regardless of the materials used or how they are configured. We decided to try embedding a coil directly into a quartz and a ceramic crucible, an internally heated crucible. The resulting prototypes were better than anything else we had used or tested, including other companies atomizers. Still we were not satisfied. Heat up wasn't very fast or efficient and accurate/real temp control still impossible. Despite our best efforts we found that indirect or internal heating with a coil just isn't capable of actual temp control or the performance you get from a directly energized surface. We always suspected it wouldn't be possible to get good temp control or performance from any indirect heating method.

Energized What?

Enter the idea to make a directly energized crucible. In our research and testing we started to wonder "What if the crucible is the coil?" The concept of a crucible directly acting as a resistance coil was entirely foreign. The very configuration is a short circuit! Other engineers I talked to didn't understand it and anyone I tried to work with basically said that to me. I made friends with a customer at the time, I helped him with some stuff and we got chatting. He had heard that I was working on a new Molecule and started asking me about it. I told him the general idea that we were working on. He asked me what was holding me back and I said resources. As it turned out, he is a surgeon and was interested in our project. Not only did he want to invest, he wanted to consult us to help make our products better and safer than they already were. He provided the capital we needed to jump start such an ambitious project.

First we had to prove the concept, it was just an idea at this point. I made the initial prototype out of stainless steel just to prove it could be done! The first energized crucible in existence was in fact an ESSC and not the ESCC™ you all know. It was a great little invention and sits framed on top of my desk. This was a major moment in our history. We had done the unthinkable, created an energized crucible! At this point our manufacturers took me seriously and work began to create the worlds first Energized Crucible Atomizer. The Energized Stainless Steel Crucible (ESSC) worked but had its own issues. With it we were able to establish that it could be done and that it was able to do temp control accurately. Performance was encouraging enough that we knew we were on the right track. Due to the issues we needed a different material though.

Creation of the ESCC™ begins.

Realizing we needed a special material we began our search for a material that would also be safe for our purposes. We found Silicon Carbide and quickly made the connection, an already popular dabbing material also happened to meet our unique material needs?! How has nobody done this? We soon discovered the answer to that question through a seemingly never ending chain of events that would lead to our growth as a company, and also me as a person. We'll come back to this and discuss that chain of events, but at this point we began prototyping Molecule22 designs and ESCC™ designs.

Molecule22 Atomizer Prototyping.

I began designing the Molecule22 as the first and only 3 in 1 system in late 2018, to be used as a wax pen, e-rig, or e-nail. This included the mod, bubbler, and the bottomless banger with 510 extension cable. It took several M22 designs to land with the current one and many ESCCs to figure out several variables with the function of the design. Many ESCCs of different designs and methods of securing were broken to find what would and wouldn't work.

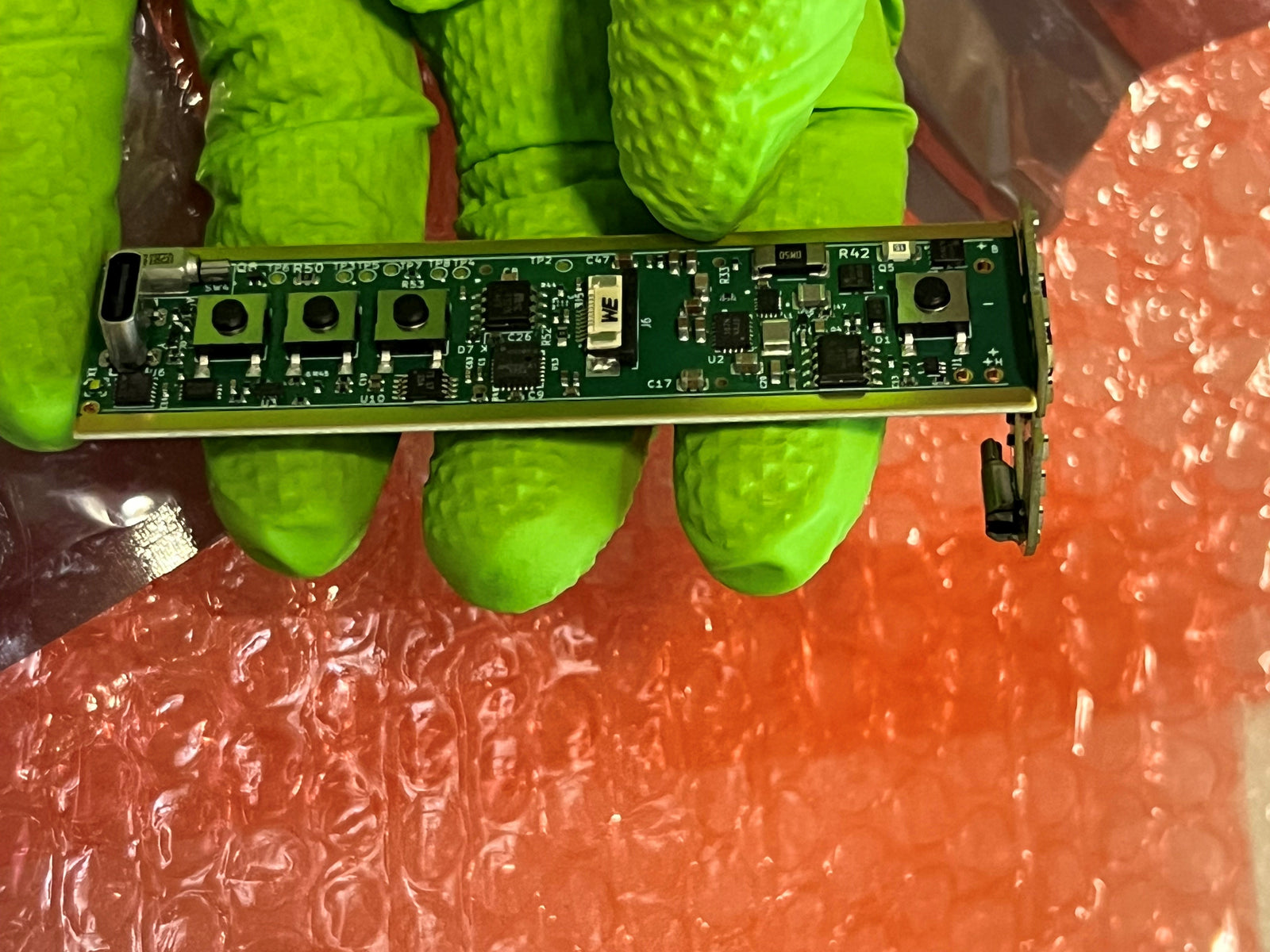

In February 2019, we got the first M22 deck with spring clips and a new ESCC™ design. I broke it almost immediately. I luckily manage to get one to work, and the first puff is taken from an ESCC™ ever. I knew right then and there we were on the right path and I had to finish this creation and make it real. It was a long way from ready for the public but enough to tell me it would be worth the effort. I knew I needed to refine the springs and the ESCC™ design to be more robust and eliminate breakage.

Morale was high and everyone at AVS was feeling great- we were on the cusp of achieving something amazing through a wonderful chain of events, and we were the right people for the job at the right time and place. We were all excited and full of energy. I had not filed my patent at this point- I needed to improve the design to further understand the ESCC's properties and collect more data for the patent filing. This was AVS "Top Secret" and we knew we couldn't let anyone have a clue what we were doing, only myself, the VP, and our investor knew what was going on at this point. We kept showing the flat coil and embedded coil in quartz to the public.

Spring Clips, how hard could it be?

It was much harder than I anticipated! We had to secure the ESCC™ using spring clips to allow for flexibility due to things like manufacturing tolerance, thermal expansion, and material hardness. I tried to work with several engineers that specialized in springs and clips, but none of them were willing to help or told me it was impossible. Heard that before and still made the ESSC and ESCC™.

The spring clip required both mechanical and electrical properties to be within certain parameters as it is not only to secure the crucible but also to establish the electrical connection. This presented a unique puzzle with many variables, one I was determined to solve and had to solve alone. I began researching and learning about springs and various materials- my knowledge from coil building over the years proved very helpful. I designed and tested many different springs until we finally got to what we felt was the best design. It worked very well and so did the ESCC™. We knew some more testing was necessary but had the data needed to file our patent. June 26th, 2019- ESCC™ and M22 patent filed! We enjoyed the moment and then got back to work to refine the design and new technology further, still keeping it secret from the public.

Loose Lips Sink Ships

I made a very bad choice, paid the price, and learned a lot. I couldn't contain my excitement and finally leaked what I was working on. I engineered this entire system nearly by myself from the ground up at this point and was on the cusp of something amazing. So I made a post to social media on July 14th, 2019 to show parts of my patent with areas redacted for confidentiality. Then again on July 18th, 2019. I revealed the ESCC™ publicly for the first time and titled the post "Are you not entertained?! Energized SiC Crucible melt.". It was one of the most commented-on posts in the community at the time and quickly spread to all sorts of forums across the internet. Hype and conversation was raging across the web, our excitement was now everyone's excitement. Sounds good right? No, it was not ready for prime time, it was only the 4th prototype of this new technology and we were still learning about it. I never should have shared that- it was too soon.

Pre-Order

People were so excited that we were getting flooded with messages and some people started to actually get very angry with us that we wouldn't let them order it yet. People saying "I don't care if I have to wait, I just want to be in line for it when it is ready." We resisted initially because of the risk. The tech was still very much unproven and in need of further refinement. We felt immense pressure from the community. I then received what I thought was the final prototype- everything was great! The issues with the previous version were addressed and we had a device ready to sell... or so we thought. We put them into production at great expense, taking a huge risk. We opened pre-order to allow people to reserve a place in line. It was all downhill from here.

Problems, problems, and more problems.

Immediately we had a few problems in the supply chain- minor hiccups that are par for the course in making a new product. We informed everyone of the delay and all was mostly well. Then they arrived. The ESCCs we got were much different than the final prototype and much lower quality. They were far too thin resulting in extremely high breakage rates. Additionally, the springs were made slightly smaller and with a different material than we specified and what was used in our sample. We had been swindled by a few of our third party suppliers with a bait and switch. The factories refused to refund us or remake the order correctly. Only one thing we could do- we turned to our reddit community (where this launch was all done through) and told them there were some big problems with the ESCC™ and spring clips. We quickly discovered these were only some of the issues. O-rings were different, and the ceramic pieces out of spec. It was a disaster.

I offered everyone a choice- a refund, or to get the M22 as it was and wait for the new parts. I was actually really surprised when only 2 people chose to cancel, but that also meant more pressure as there were hundreds of redditors eagerly waiting for me to fix this. So I set off with determination and confidence knowing I could fix this. Every time I solved one problem, three more were presented to me. This had never been done before because it was very difficult to do and required some serious R&D and several kinds of engineering. I am the primary engineer at AVS, and this project requires more than one person. We hired 2 other engineers in this process to assist me, mostly to speed things up and to back me up where my knowledge fell short. Like many people I have worked with in my life I learned a lot from both of them and am a better, more well rounded engineer for it.

Problems Solved!

I found new factories and had samples made from all of them and I re-worked or re-engineered all the parts including the springs while engineering our mod and the other accessories as well as designing this site you're looking at. We also put a lot of resources and R&D into modifying our SiC material to have a TCR compatible with most mods on the market at the request of redditors. A lot of research went into this and we finally had solved the puzzle. Things were looking great and excitement was rising at AVS and we announced to everyone that we had solved the puzzle. Hurrah! Right? Well not quite.

Coronavirus... ☠☠

Enter the Coronavirus Pandemic which was impacting our suppliers as early as December of 2019. Supply chain issues began again, with nobody giving us clear answers. Here we were with the puzzle cracked and finally thinking we had it in our hands just to be given the run around. Finally news breaks of the virus and they admit that they were running at 1/8th capacity. In the midst of the chaos they attempted to get us some ESCCs and parts so we could at least show that we had indeed accomplished it to ease rising impatience and tension in our community. But they switched the SiC material batches and used the wrong formulation. In our research to learn about the electrical properties and modifying the TCR, it took many batches of SiC with a different variable changed each time to fully understand the impact of each variable. We got 100 ESCCs that were way out of spec and didn't work for this. This was another disaster. It was January 2020 at this point and they left for Chinese New Year. Customers were understandably getting angry at this point and wanting answers. I made a video and posted it doing all I could to ease rising tension and reassure everyone this was solved and just a waiting game, nobody had any idea what was about to happen next- the full blown worldwide pandemic.

This of course halted production and then lead to further delays. Production slowly picked back up but it took until July of 2020 to fulfill our original commitment to the customers. Most of them patiently waited, some impatiently, and some very vocal about their impatience. Ultimately only 7 people took refunds in the end. Many that had been vocal about their dissatisfaction came back and ultimately said it was worth it. There is always more to the story, such as the first car accident I've ever been in, not my fault, totaling my vehicle and sending me to the ER during all this. That added to the delays and of course a few more things in our lives here at AVS I'm not saying due to their more personal nature. All in all, 2020 has been a year no one will soon forget.

The end result.

The revolutionary Molecule22 with ESCC™, the highest quality and most innovative concentrate vape ever made.

This is just the beginning.

Per aspera ad astra!

Max

January 13, 2021

What a journey! After reading this I’ve found new appreciation and respect for Brent and AVS. I’m looking forward to my M22, and more AVS products in the future.